About Chinaplas:

Over 380,000 sqm of Shanghai National Exhibition & Convention Center, with 4,420+ exhibitors from 40+ countries and regions, Chinaplas is Asia’s No.1 and the world’s No.2 plastics and rubber trade fair, focusing on the raw materials, equipment and new technologies of the plastics and rubber industry.

Table of content

1. General Overview of Chinaplas

2. 410+ Companies Active in Sustainable Offers

3. Daydream: B2B Tailor-made Projects in Europe / Asia / North America

4. Appendix

1. General Overview of Chinaplas

The 2024 Chinaplas showcased the dynamics of the plastics and rubber industry, attracting an impressive turnout of over 4,420 exhibitors. Among them, two-thirds are Chinese exhibitors and one-third are from overseas. These exhibitors presented a diverse mix of segments, leading technologies and trends of the global plastics and rubber industry.

2. 410+ Companies Active in Sustainable Offers

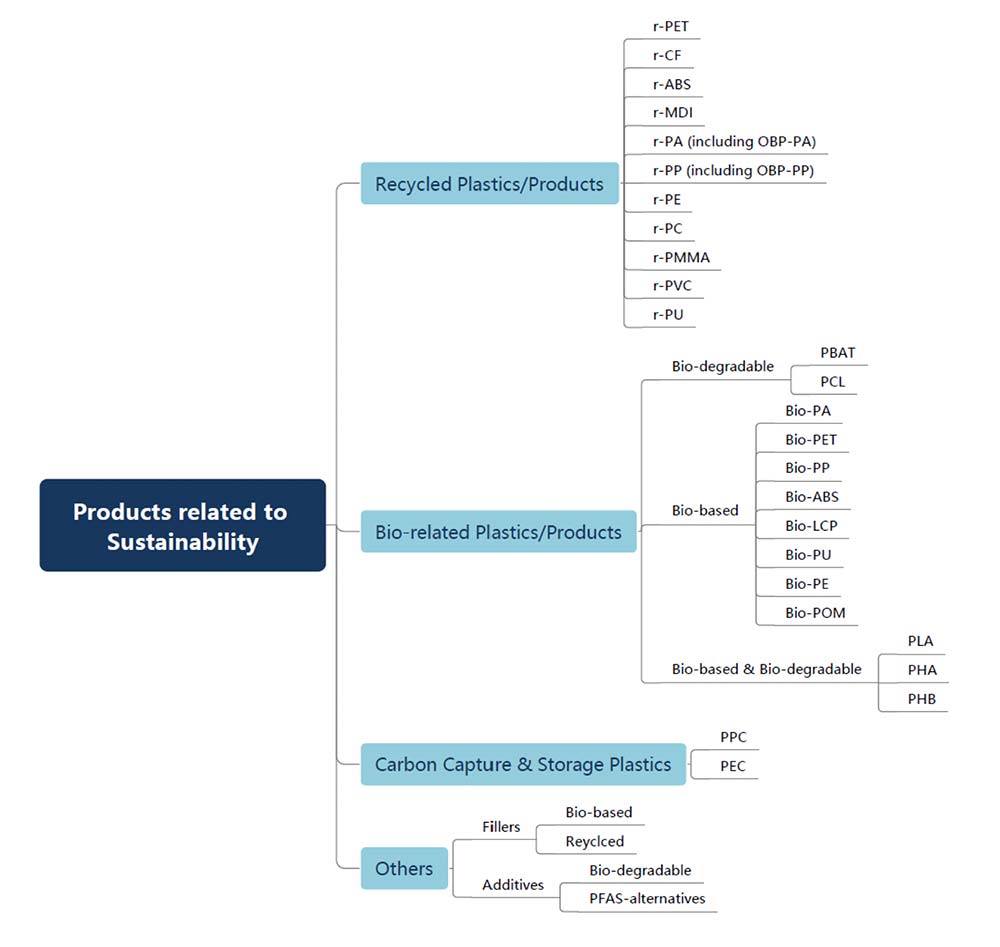

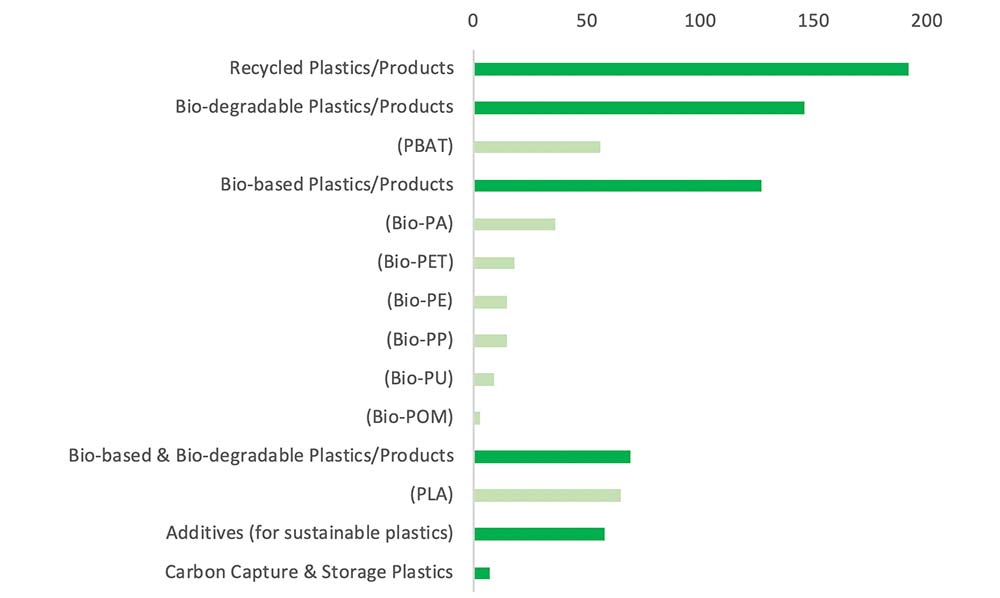

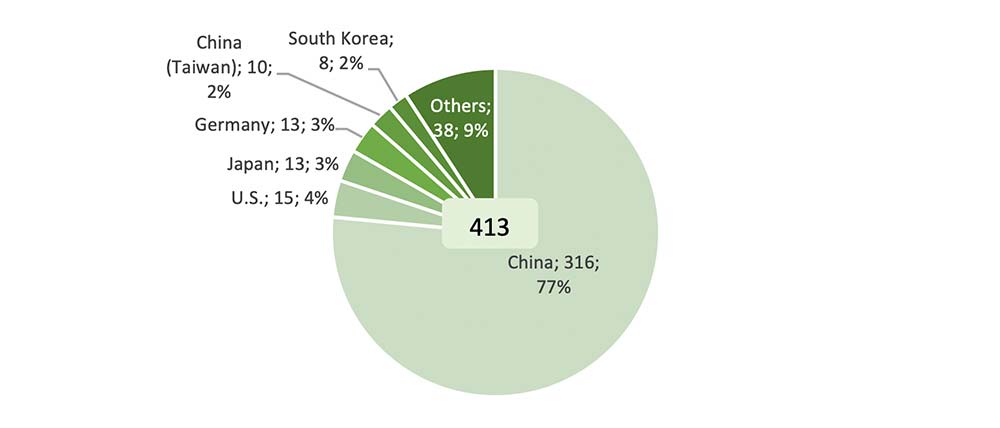

Sustainability has always been a concern for the plastics industry. In our surveys and research, 10% of the exhibitors offered products related to Sustainability. Daydream categorized their sustainable offerings into the following types (Fig 1)

- Recycled Plastics/Products

- Bio-related Plastics/Products

- Carbon Capture & Storage Plastics

- Additives and Fillers

Fig 1: Category of products related to Sustainability

Among the 413 companies offering products related to Sustainability, 192 companies provide Recycled Plastics/Products, followed by companies offering Bio-degradable Plastics/Products and Bio-based Plastics/Products.

Fig 2: Number of Exhibitors Having Sustainable Offerings by Product Category

*Due to differences in statistical criteria, the Bio-based category may include products like PLA and Starch source cellulose.

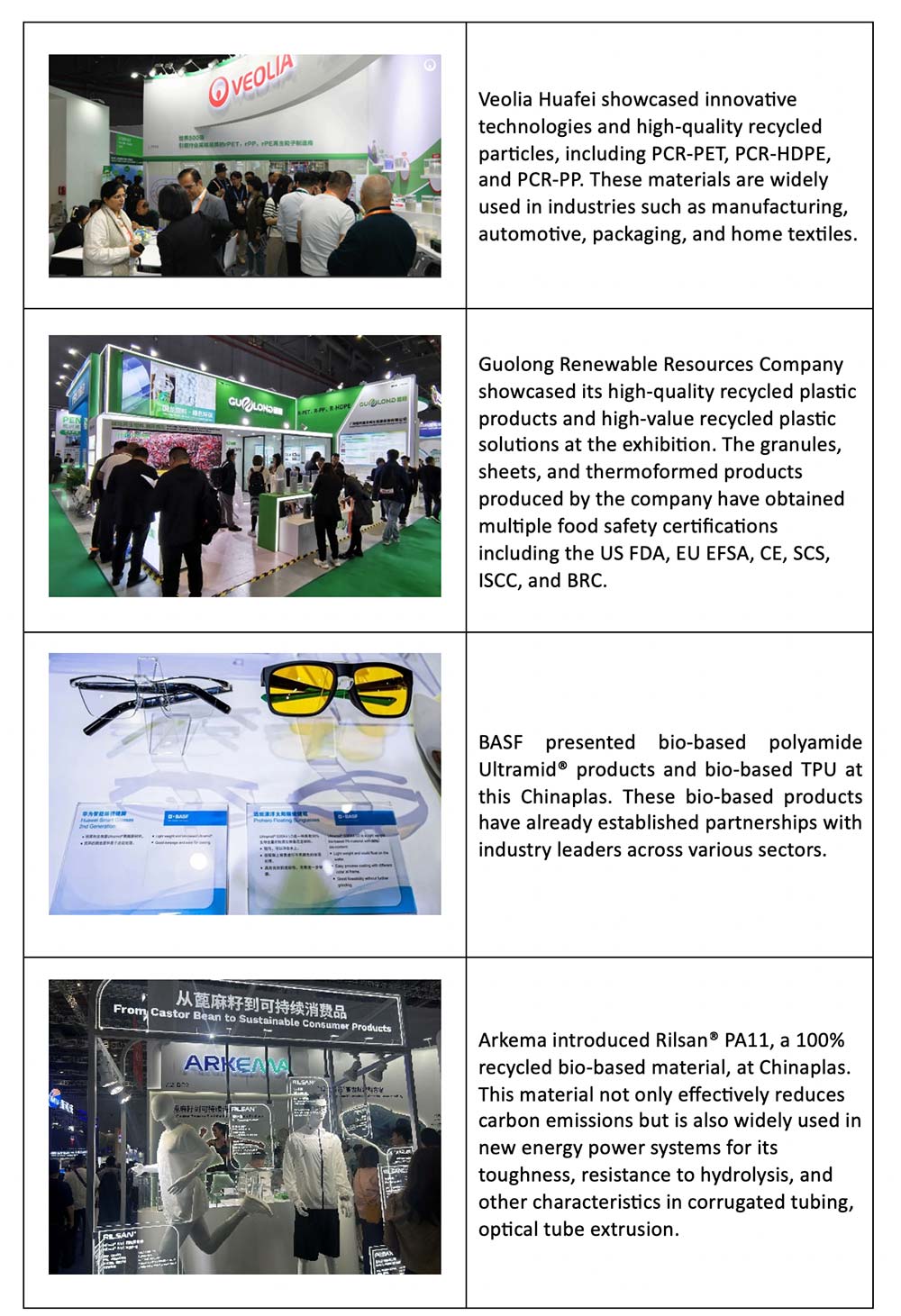

In the following sections, Daydream listed some of the products related to Sustainability brought by exhibitors at the show.

2.1. Recycled Plastics/Products

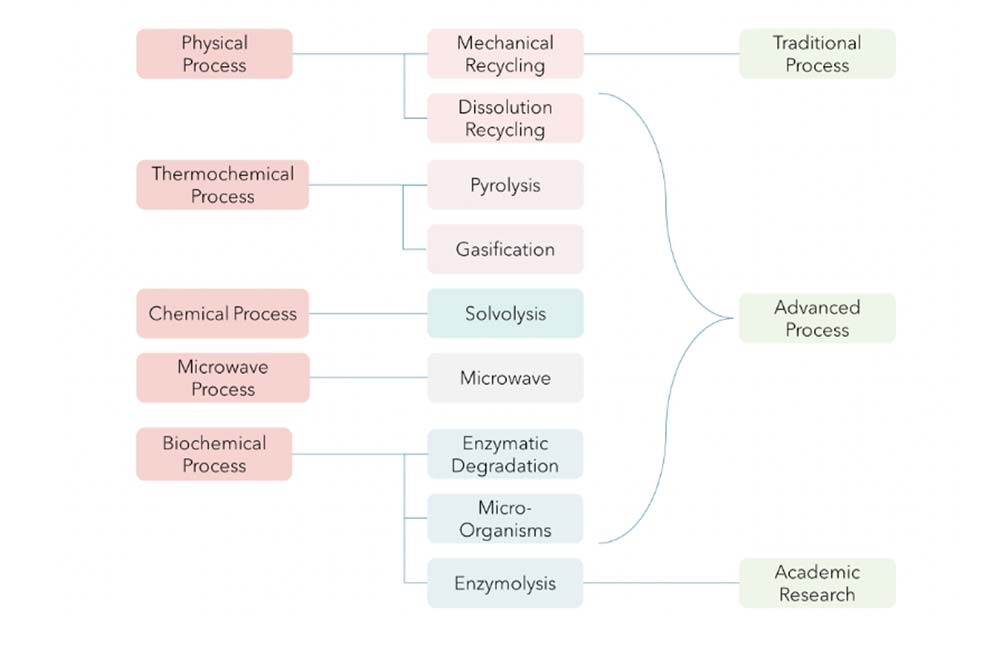

Mechanical recycling is a traditional process that is commonly used for plastic recycling. In recent years, there have emerged several advanced recycling processes such as pyrolysis, gasification, solvolysis and microwave.

Fig 3: Diversity of Recycling Method

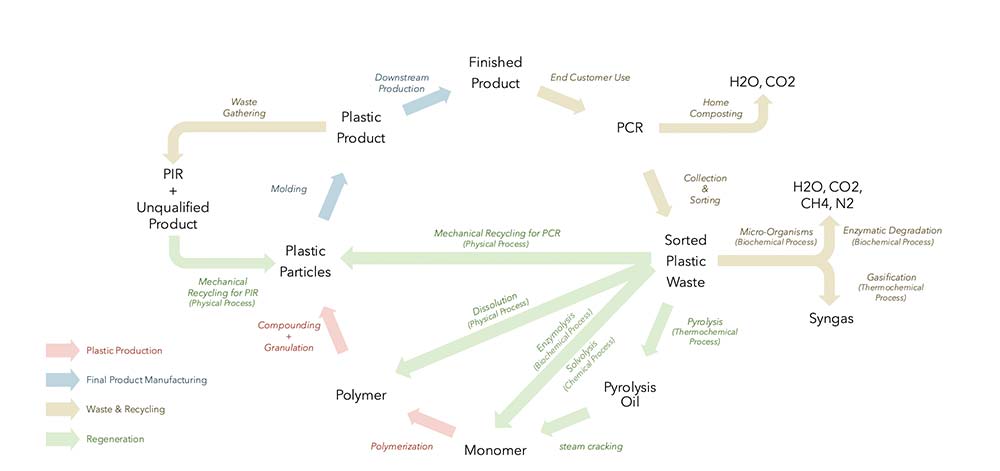

Fig 4: Plastic Product Recycling Process

PCR: Post-Consumer Recycled

PIR: Post-Industrial Recycled

In the Recycled Plastics/Products category, there was a notable difference from previous years, which is that besides traditional mechanical recycling solutions, many companies also presented advanced recycling solutions and products. This year, a total of 192 companies showcased related solutions.

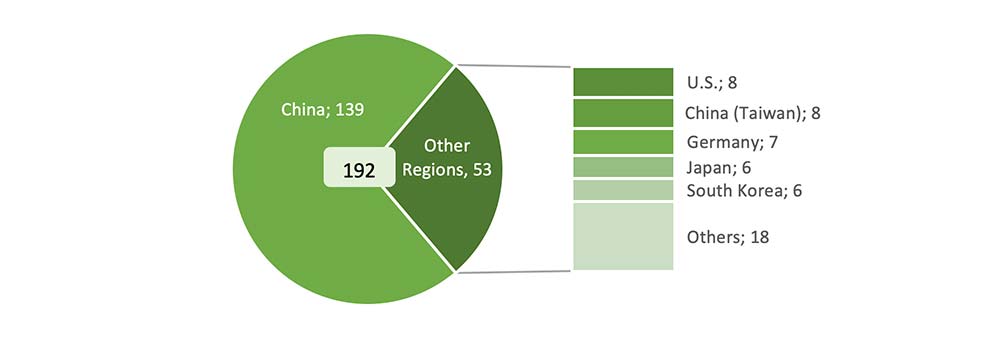

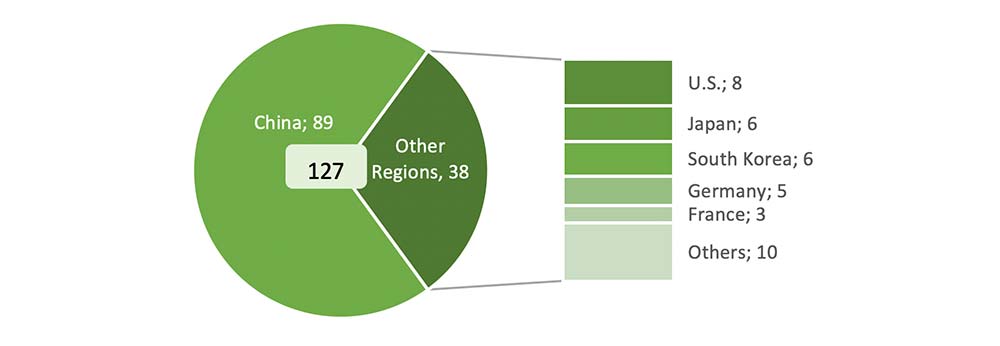

Fig 5: Number of Exhibitors Offering Recycled Plastics/Products by Country

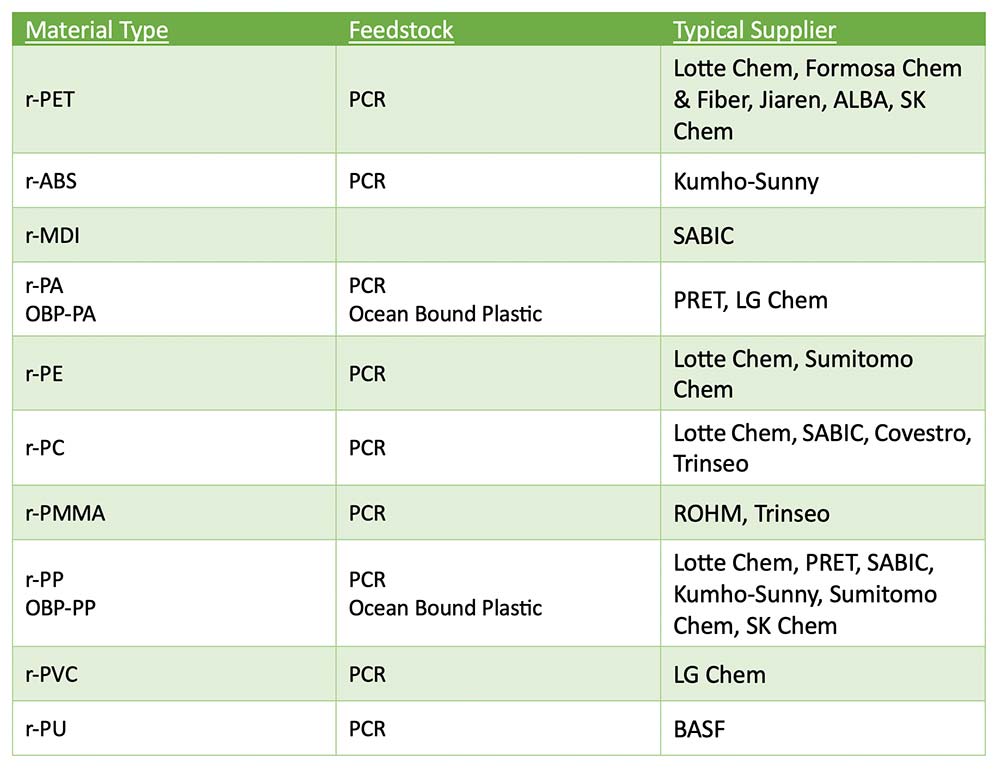

Table 1 Examples of Recycled Plastics/Products at The Show

2.2 Bio-related Plastics/Products

2.2.1. Bio-degradable Plastics/Products

In the Bio-degradable Plastics/Products category, many companies provided PBAT and PCL products this year. However, some issues exist, such as the actual capacity of PBAT production.

Fig 6: Number of Exhibitors Offering Bio-degradable Plastics/Products by Country

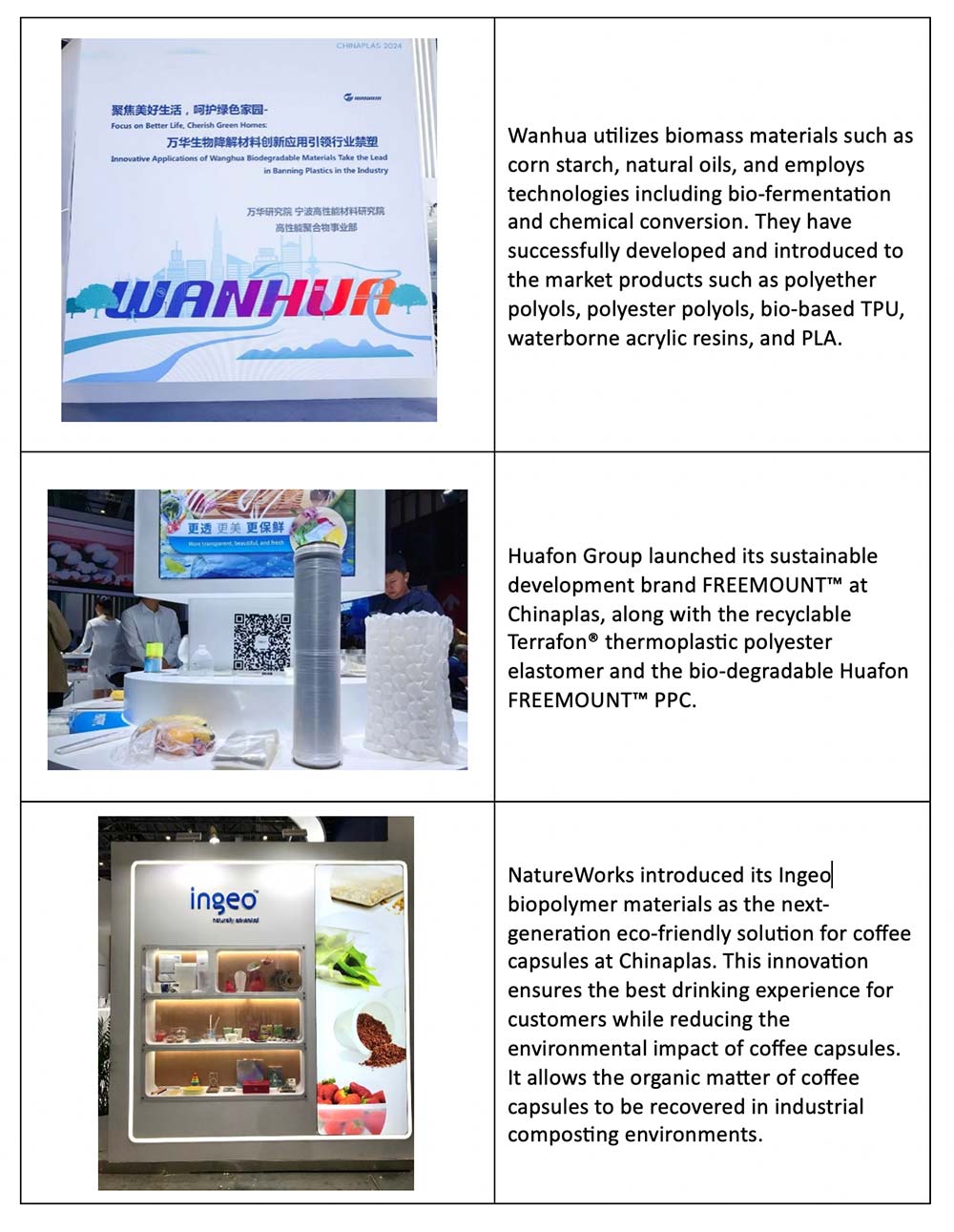

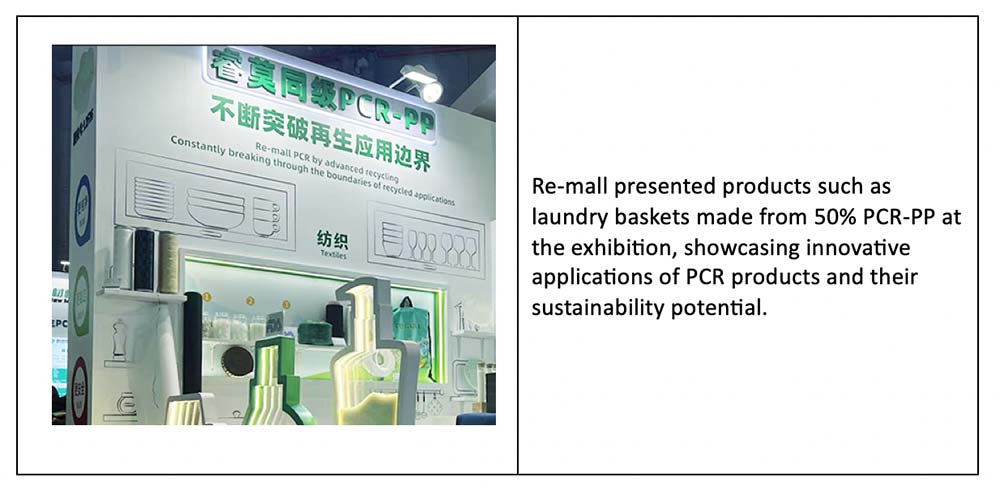

2.2.2. Bio-based Plastics/Products

In the Bio-based Plastics/Products category, the sources of bio-based raw materials are becoming more abundant. Manufacturers began to innovate in research and development.

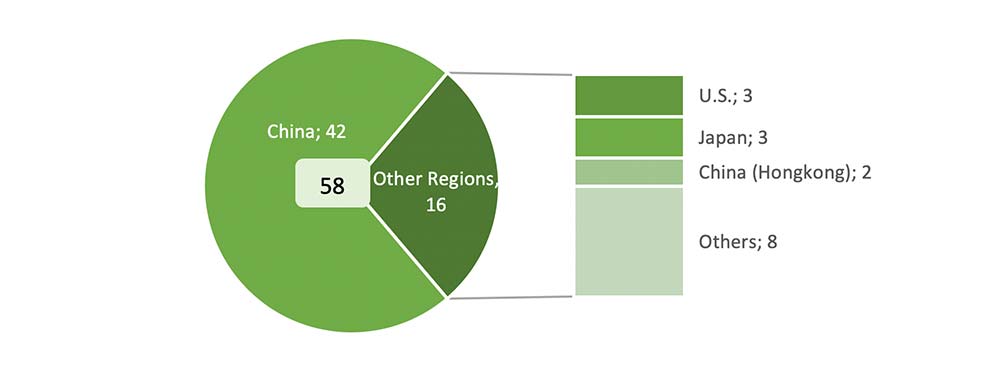

Fig 7: Number of Exhibitors Offering Bio-based Plastics/Products by Country

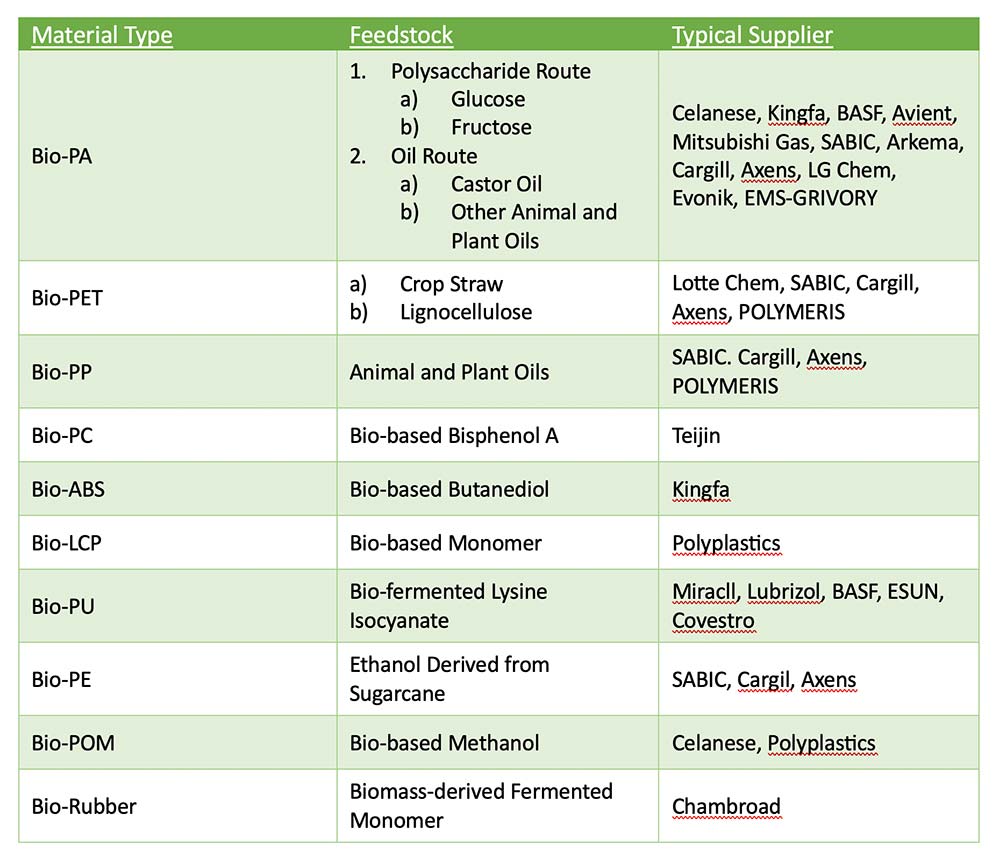

Table 2 Examples of Bio-based Plastics/Products at The Show

2.2.3. Bio-based & Bio-degradable Plastics/Products

In the Bio-based & Bio-degradable Plastics/Products category, PLA products are the focus. Total Energies Corbion, NatureWorks, ESun, and BBCA have introduced the application of PLA in fibers, textiles, and clothing products, expanding the downstream applications of PLA from the previously common disposable products to everyday consumer goods. PHA, PHB products are also covered in this category.

Similar to PBAT, domestic manufacturers in China are continually investing in the PLA industry, leaving people to wonder whether the excessive accumulation of capacity has far exceeded market demand. Furthermore, developing a more diverse range of downstream applications for PLA and addressing the challenge of modifying PLA performance will be crucial for many manufacturers in the future.

Fig 8: Number of Exhibitors Offering Bio-based & Bio-degradable Plastics/Products by Country

2.3. Carbon Capture & Storage Plastics

In the Carbon Capture & Storage Plastics category, several companies brought in their latest products. For example, Huafon introduced the FREEMOUNT™ PPC product, which utilizes carbon dioxide as its primary raw material and has superior degradability. This product not only aligns with the national “carbon neutrality” direction but also supports the promotion of plastic reduction policies. LG showcased PEC products based on carbon dioxide, combining CO2 captured from factories with ethylene oxide. Currently, the main downstream applications are cosmetics containers and food packaging.

Fig 9: Number of Exhibitors Offering Carbon Capture & Storage Plastics by Country

2.4 Additives for Sustainable Plastics

In the Additives category, there are mainly two major trends relevant to sustainability: Bio-degradable and PFAS-free.

Fig 10: Number of Exhibitors Offering Additives for Sustainable Plastics by Country

Bio-degradable additives: Fine-Blend introduced their newly developed recyclable Eco-batch® series of compatibilizers and the biodegradable Bio-Master® series. These additives enable effective compatibility with recycled resins, enhanced reactivity for biodegradable resins, and efficient bonding for photovoltaic energy materials.

PFAS-free additives: Concerns about PFAS were also a significant topic at this year’s Chinaplas, with many companies introducing solutions to address the issue. For example, Clariant unveiled its new AddWorks PPA series at Chinaplas, primarily targeting the polyolefin film extrusion market. Trinseo developed PC and PC/ABS products with flame retardants that are free from PFAS. Avient showcased PFAS-free LubriOne internally lubricated formulations, suitable for gears, pulley mechanisms, and conveyor systems in automotive sunroofs, seat mechanisms, and mirror sliding parts.

Besides PFAS-free additives, some companies also introduced alternative solutions to PFAS polymers. For example, VICTREX provides PEEK products that can meet various application scenarios such as food contact and tribological applications, making them ideal alternatives to PFAS polymers.

(In 2023, new regulations from both the European Union (EU) and the United States of America aim to greatly curb the prevalence of PFAS in the environment. The European Chemical Agency (ECHA) has proposed legislation that will ban all PFAS from being manufactured or used in the European Union by 2027. Following the EU, the EPA in the United States announced (March 14, 2023) a new policy that enforces strict monitoring of six different PFAS in drinking water.

For more information about PFAS, please refer to: How can Daydream-Dynovel help you embrace stringent PFAS regulations? https://www.daydream.eu/how-can-daydream-dynovel-help-you-embrace-stringent-pfas-regulations/)

2.5 Fillers

In addition to polymers, compounds, and additives, some companies are also committed to making fillers more sustainable. For the Fillers relevant to sustainability, it is primarily divided into two major types: Bio Filler and Recycled Filler.

- The bio-based long cellulose fiber filler of Polyplastics is a representative type of Bio Filler that meets customers’ demands for maintaining mechanical strength while using bio-based materials.

- Mitsubishi Chem rCF: Utilization of recovered carbon fiber reinforced plastics (CFRP) to produce carbon fibers, which are then used as modified raw materials for polycarbonate resin. This method of utilizing recycled carbon fibers helps reduce carbon dioxide emissions during manufacturing. Compared to virgin carbon fibers, recycled carbon fibers can reduce carbon emissions by one-eighth.

Among the 413 companies offering products related to Sustainability, the majority were Chinese companies, totaling 316, followed by U.S., Germany, and Japan, with 15, 13, and 13 companies respectively.

Fig 11: Number of Exhibitors Having Sustainable Offerings by Country

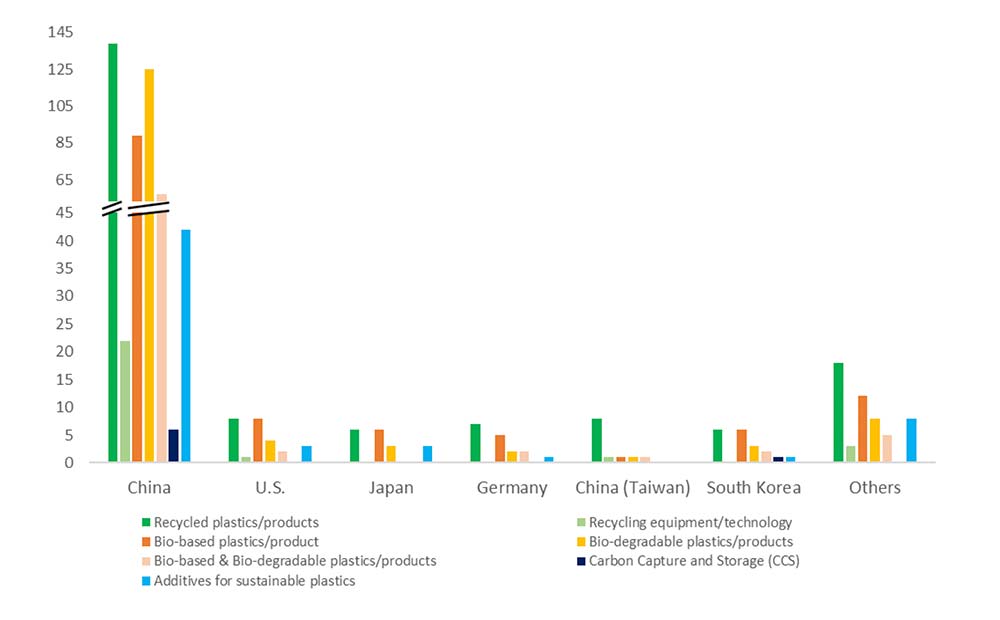

Fig 12: Number of Exhibitors Having Sustainable Offerings by Country and by Category

In our statistics, most countries have at least one or more exhibitors offering products, solutions, or services related to Recycled Plastics/Products and Recycling Equipment/Technology. Among them, China has the most, with 139 companies related to Recycled Plastics/Products and 22 companies related to Recycling Equipment/Technology.

In the Bio-related Plastic/Products category, which includes Bio-based, Bio-degradable, and Bio-based & Bio-degradable plastic/products

- China: more exhibitors presented products related to Bio-degradable Plastic/Products, with the proportion reaching 46%.

- Most countries/regions except for China: The proportion of companies related to Bio-based Plastic/Products exceeds 30% of the total number of Bio-related Plastic/Products exhibitors

As sustainable development continues to advance worldwide, many chemical companies have put forward their sustainability goals for 2025/2030, for example

BASF aims to process 250,000 metric tons of recycled and waste-based raw materials annually from 2025, replacing fossil raw materials

Toray targets to source 20% of raw materials from recycling, derived from biomass, or produced with CO2 recycling used in core polymers (PET and nylon polymers) in FY 2030

LyondellBasell aims to produce and market at least 2 million metric tons of recycled and renewable‑based polymers annually by 2030

Total Energies sets an ambition to reach 1 million tons of circular polymers by 2030

Dow and Mura Technology plan to build multiple 120 KT advanced recycling facilities in the U.S. and Europe, collectively adding as much as 600 KT of annual capacity by 2030…

The sustainability goals set by these chemical companies can not only fulfill their own commitments to reducing carbon footprints, but also respond to customers’ needs for using sustainable products (e.g., recycled plastics, bio-related plastics) and assist customers in carbon footprints reduction.

3. Daydream: B2B Tailor-made Projects in Europe / Asia / North America

Daydream has performed multiple projects in the B2B material industry over the last decade, across the manufacturing value chain from raw materials to products.

We have realized more than 120 projects in Plastics & Polymers across the manufacturing value chain from raw materials to final polymer products (film, compounds etc.) for B2B players, most of them being the largest in the field.

Since 2000, Daydream & Dynovel have proven offers in:

- Market & Business Strategy

- New Business Development

- Sustainability & Digitalization

- People Management – Training & Workshops

- Business Improvement for Market and Sales (Market Segmentation, Client Segmentation, Channel-to-market, Business & Go-to-market Plan, M&A Scouting, Capex project…)

Since 2000, Daydream & Dynovel have:

- Over 120 B2B clients

- Three offices: Cologne for Europe, Philadelphia for Americas, Shanghai for Asia

- One unique best-in-class methodology and a team of engineers and PhDs

- A unique methodology & experiences

- A large network and knowledge

4. Appendix

In the exhibition, there were many sustainable materials, and Daydream listed a few representative products suppliers as follows: